Project Description

Cement Waste Filling is filling the cavities formed as a result of production processes in underground mining enterprises with large grain size material. In this filling system, which is also called rock filling, as a material; Side rock formed as a result of production, quarry wastes and aggregate formed as a result of blasting, large-sized materials that are removed for open pit production, pickling, ore preparation facility waste, various furnace slags, rock waste formed as a result of metal heap leaching and natural river gravel are used. Filling material is obtained by combining the materials with water, cement and binding materials in determined proportions and is used in the process of filling underground cavities.

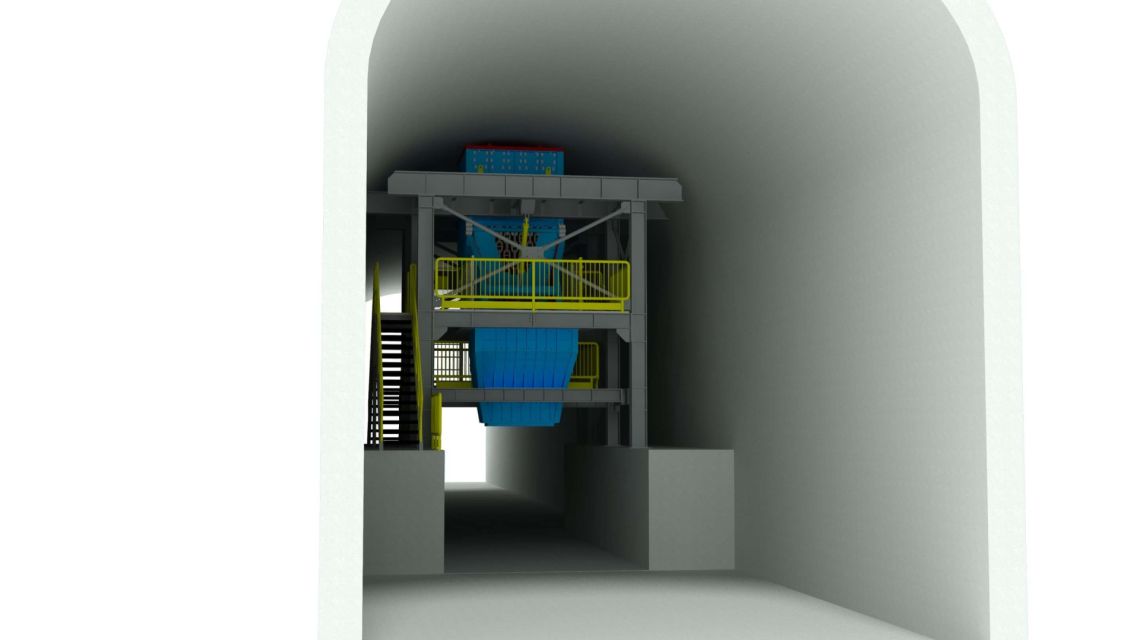

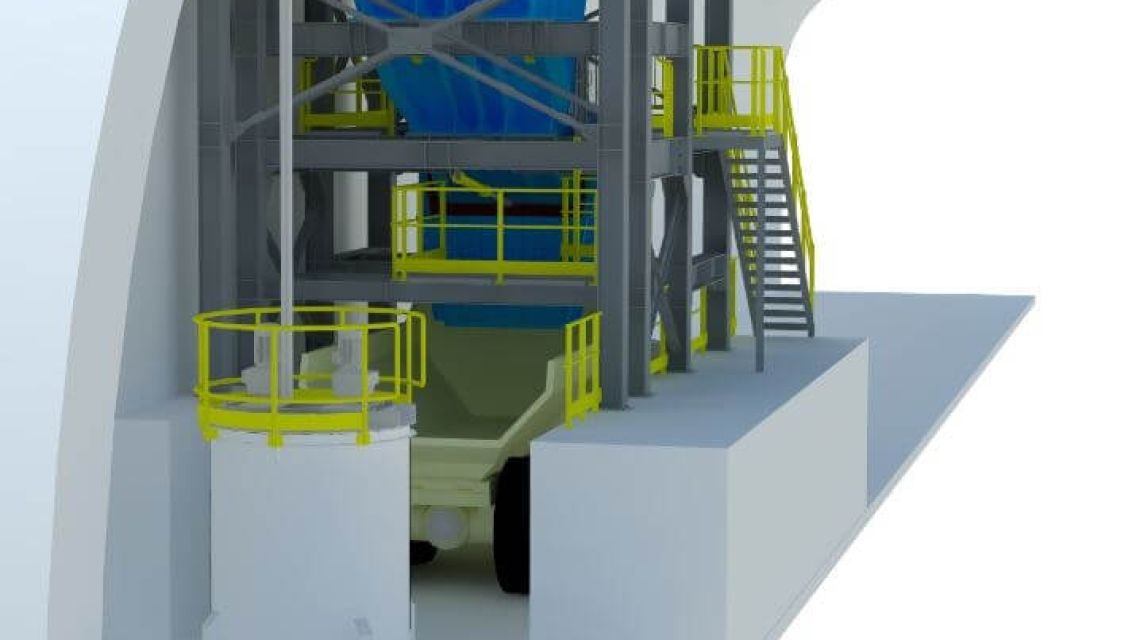

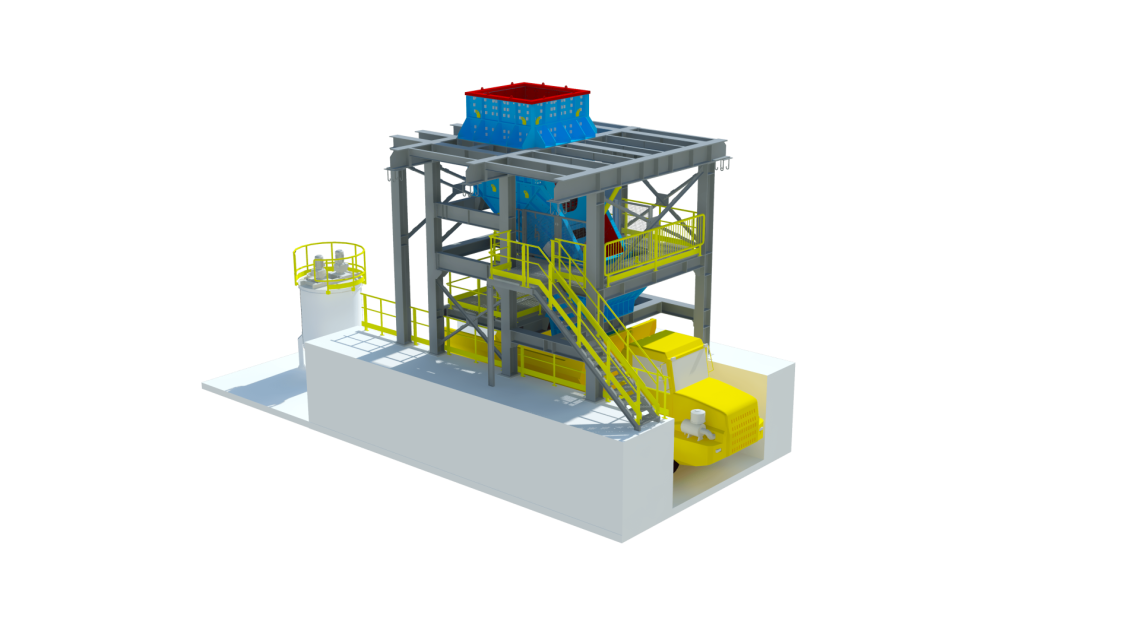

At the Cement Waste Filling Station, when the materials passing through the grizzly screen reach the transfer chute, the mixture prepared in the grout tank is sprayed onto the material to obtain the filling material and loaded onto the truck. After this stage, the filling process is done how the filling will be placed in the underground cavities.

All design, manufacturing, assembly and testing processes of Cement Waste Filling Station are carried out by Çolakoğlu Makina and it is supported in all technical matters.

Technicial Specifications

The sections in the project;

- Cement Waste Filling Station main steel structure,

- Upper throat chute, intermediate steering chute and lower loading chute,

- Grizzly grill and steel grille chassis,

- Aboveground grout tank,

- Underground grout tank,

- Pump and pumping pipelines,

- Electric-automation control system,

are listed as.